Call Us : +8613506813068

- Home Page

- Company Profile

-

Our Products

- TTR Slitting Industry

- Cheap Price TTR Slitter N1

- Tracking Code Printing Machine

- Fully Automatic Notch Cutter Machine

- Good Price TTR Slitter N1

- Automatic Barcode Ink Ribbon Cutter Rewinder

- Cheap Barcode Ribbon TTR Converter Rewinder Machinery

- TTR Paper Core

- Ttr Paper Plastic Core Tracking Code Printing Machine Clx001

- TTR slitting rewinding machine

- TTR Slitting Machine

- Thermal Transfer Ribbon Slitter

- Plastic Core for Snap Printer Paxar Printer Markem Printer Monarch Printer

- Plastic Core For Barcode Roll

- thermal transfer ribbon slitting machine

- TTR slitter

- TTR cutting machine

- Barcode ribbon slitter

- Barcode ribbon cutting machine .

- Thermal transfer ribbon slitting machine

- Thermal transfer ribbon slitter rewinder

- Barcode ribbon producing machine

- Thermal transfer ribbons slitter machine

- Thermal transfer ribbons rewinder machine

- thermal transfer ribbon rewinding machine

- thermal transfer ribbon slitting rewinding machine

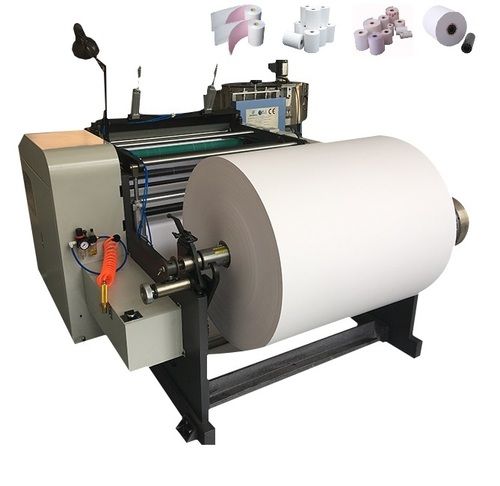

- Thermal Paper Slitter

- Cash Register Rolls Slitter with Packaging Line

- Automatic Thermal Paper Slitter Rewinder Machine CP-S1100A

- POS Roll Slitter Rewinder Machine CP-S1100AW

- Automatic Thermal Paper Slitter Machine

- Cheap Manual Thermal Paper Slitting Machine CP-S900C

- Good Price Coreless Thermal Paper Slitter Machine

- Manual Thermal Paper POS Slitting Rewinding Machine

- Till paper slitting and rewinding machine

- thermal paper roll rewinder machine

- thermal paper roll slitter machine

- ATM Rolls Slitter and Packaging Line CP-S1200A

- Automatic Paper Roll Slitting Machine

- 1 Color Flexo Printing For Thermal Paper Slitting Machine

- 3 Layers Thermal Paper Slitter Machine

- China quality supplier POS Paper Slitter Rewinder Machine

- Factory Direct Price Thermal Paper Making Machine

- thermal paper roll rewinding machine

- thermal paper roll slitting and rewinding machine

- thermal paper cutter and rewinder machine

- thermal paper cutter

- thermal paper rewinder machine

- till paper slitting machine

- till paper rewinding machine

- till paper slitting and rewinding machine

- till paper slitter machine

- till paper cutter

- till paper slitter

- till paper rewinder

- receipt paper roll slitting machine

- receipt paper roll rewinding machine

- ATM paper slitter

- ATM paper rewinding machine

- Cash paper slitter machine

- ECG paper slitting machine

- POS paper slitting machine

- cash register paper slitting machine

- Cash register paper rewinding machine

- cash register papaer slitting rewinding machine

- THERMAL PAPER SLITTER

- Cash register paper rewinder machine

- Cash register paper roll slitting machine

- Hot Stamping Foil Slitter

- Film Slitter

- Inspection Rewinder

- Other Products

- Ttr Slitter

- Thermal Paper Slitting Machine

- Film Slitting Machine

- Paper Slitting Machine

- Paper Rewinding Machine

- Rewinding Machine

- Slitting Rewinding Machine

- Resin Barcode Ribbon

- Fabric Slitting Machine

- TTR Slitting Industry

- Contact Us

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese